Products

Shuttle racking system is characterized by high storage density, high access efficiency and high management ability over more varieties of goods. Either FIFO or FILO modes can be configured. It is not necessary to drive forklift into the aisle of racking. This racking system is composed of intelligent shuttle and shuttle racking, and can be also integrated with automatic stacking system to form automatic storage system.

As shuttle racking system does not require drive of forklift into aisle, the operation time can be reduced by a half. In addition, compared with drive-in racking, it requires much less forklift. It is suitable for warehouse with high goods turnover, and is characterized by easy access, allowing placement of different goods on different guide rail levels, and higher storage area use rate.

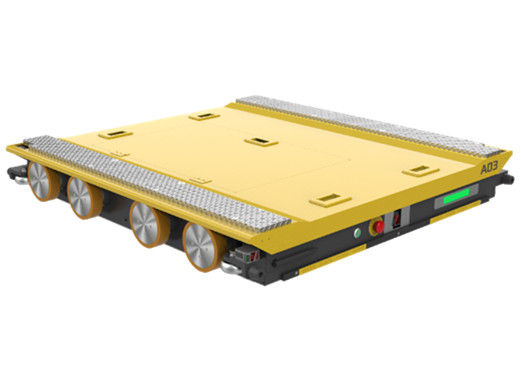

In shuttle racking system, specified quantity of goods can be deposited or taken out. In addition, during forklift waiting period or when needed by goods sorting, the shuttles can automatically move the pallets in deep position of the rails to the output end, so that the warehouse-in/out efficiency can be greatly increased. The intelligent shuttle has checking and counting function, and can provide warehouse keeper with accurate statistical data.

Shuttle racking is composed of upright, link pole, beam, adjustable foot, arm, pallet guide board, galvanized pallet support rail, protector, and forklift positioning plate. The arm beam connects the upright and the pallet support rail to form an integral unit, and horizontal bar can be configured, so that the precision of the racking can be guaranteed while the overall stability can be effectively enhanced. The adjustable feet of the upright frame with high strength bolts, which can not only ensure the installation precision of the guide rail in horizontal direction but also effectively mitigate the impact caused by uneven subsidence of floor. Pallets are placed on the upper surface of the guide rail and intelligent shuttle runs on the lower part of the guide rail. Wide opening design is used for the upper part of the guide rail, so that the intelligent shuttle can be conveniently placed into the guide rail. The optimal aisle depth of shuttle racking is not more than 25 goods locations.