Products

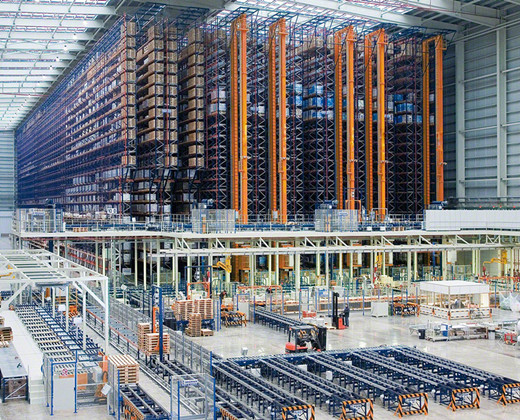

Automatic three-dimensional warehouse is a complex automation system composed of three-dimensional racks, stackers, conveyors, size detection barcode reading systems, communication systems, automatic control systems, warehouse management systems WMS, warehouse control systems WCS, and other auxiliary equipment.

The use of three-dimensional warehouse equipment can realize the rationalization of high-level warehouses, automation of access, and simplified operations. The automated three-dimensional warehouse can be connected with the production line system and enterprise management system, which can truly save manpower, save energy and reduce consumption, and realize information management and efficient operation. Computer and barcode technology are adopted on management

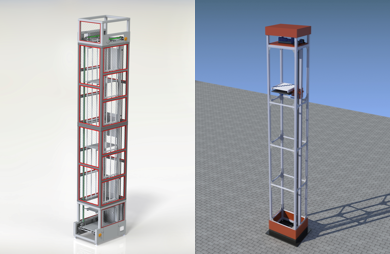

Stacker

Function: The stacker is a special lifting equipment for three-dimensional inventory and taking unit cargo. It runs in the lane between racks and is the core equipment of automatic storage. It can improve the utilization of warehouse space and the efficiency of the storage system. Manual intervention. High-precision addressing methods such as bar codes and laser ranging enable the stacker to run with high precision.

Equipment type: Single-column stacker, Double-column stacker

Advantage:

* Aluminum alloy structure, beautiful appearance, effectively reduce the weight of the whole machine

* High-frequency and high-efficiency picking, suitable for high-speed turnover bin storage system

* Synchronous belt transmission mechanism, stable speed

* High efficiency and low noise

* Traveling and lifting adopts servo drive technology to ensure high acceleration and high-speed characteristics

* Infrared communication, ensuring communication convenience and stability

AGV

Function: The AGV trolley guides the trolley to move by itself through laser guidance or electromagnetic guidance device, and can efficiently and reliably deliver goods to the destination without interfering with each other. It has safety protection and various transfer functions There is no need for a driver, and the power source is a rechargeable battery, which belongs to the category of wheeled mobile robots. The application of AGV greatly reduces people's labor intensity, improves logistics transportation efficiency, and reduces logistics costs.

Equipment Type: Fork type, back type, traction type

Features:

Green and energy saving, adopt lithium iron phosphate battery to avoid environmental pollution;

High degree of automation, can automatically charge and discharge static electricity by itself;

Strong power, flexible control, accurate positioning and high operation efficiency;

The function and exterior design are ergonomic and modern.

Shuttle/RGV

Function: The shuttle car is also known as a track-type automatic guided vehicle. It is a device produced along with an automated logistics system and a three-dimensional warehouse. It can be used as a peripheral device of the three-dimensional warehouse and can be automatically connected with other logistics equipment, such as access to the warehouse platform Various buffer stations, conveyors, elevators, robots, etc.; can also be used as an independent system to carry materials according to the plan, and different types of shuttle cars to meet different needs of customers.

Equipment Type: Straight Shuttle, Circular Shuttle, One Track Double Car

Features: Shuttle cars do not require human operation, fast running speed, reliable and stable performance, and can improve operating efficiency.

The characteristics of the smart shuttle: greater storage density, higher degree of automation, safer and more stable system operation

Conveyor

Function: Conveyor is a conveying machine for conveying materials on a certain line. The conveyor can carry out horizontal, inclined and vertical transportation, and can also form a space transportation line. It can be transported in a single unit or in a horizontal or inclined conveyor system with multiple units or with other conveyor equipment to meet the needs of different forms of operations.

Equipment type: Chain conveyor, roller conveyor, belt conveyor, chain plate conveyor

Features:

Can continuously carry materials, high throughput, large conveying capacity, light operation and simple structure;

Can meet the various special needs of different customers, with high flexibility and efficiency;

Quick and easy installation and maintenance.

Elevator

Function: It is used to move materials between two conveying lines with a large height difference. The equipment has a large lifting height and a fast lifting speed. It can be used to move materials between different floors of the warehouse, and it can also be used to move materials between the racks of a large intelligent storage system.

Equipment type: continuous hoist, reciprocating hoist

Features: Intelligent, efficient, flexible, safe and brand-new modular conveying platform;

Flexible, quiet running, energy-saving drive solution

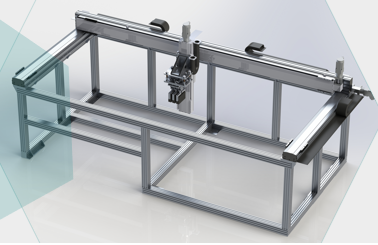

Robot hand

It can be used in harsh environments, can work for a long time, easy to operate and maintain.

It is used in industrial production fields such as dispensing, dripping, spraying, palletizing, sorting, packaging, welding, metal processing, handling, loading and unloading, assembling, and printing.

It has significant application value in replacing labor, improving production efficiency, and stabilizing product quality.

WMS

The intelligent warehouse management system (WMS) mainly supports downloading data such as outbound orders, inbound orders, production plans, BOM lists, etc. from the host system, and uses a self-developed workflow engine technology, highly customized, and can add functions at any time in subsequent implementations to solve In-program personalized development and user-defined process expansion.

WCS

The warehouse control system (WCS) is used in warehouse management to coordinate the operation of various logistics equipment. It mainly optimizes the task decomposition and analysis of the execution path through the task engine and message engine to provide execution guarantee and optimization for the scheduling instructions of the upper-level system to achieve various equipment systems. Interface integration, unified scheduling and monitoring.

One-stop logistics solution

According to customer needs, we understand the area and environment of the warehouse, the nature of the stored goods, the weight of the goods, the specifications of the cargo space, etc., carry out detailed planning and design, provide reasonable solutions to meet the needs of customers, after signing the contract, the design department will carry out professional design of machinery and software, the production department performs production and processing according to the design and manufacturing drawings. The project implementation department provides customers with a perfect turnkey project through mechanical installation and electrical commissioning.